Products & Applications

Product Categories

○ Product Details

LPCVD low-pressure chemical vapor deposition equipment is one of the important processes in the manufacture of semiconductor integrated circuits. This equipment is mainly used for the growth of 4-8 inch silicon wafers SiO2-LTO TEOS, SIPOS-oxygen-containing polysilicon, SI3N4-silicon nitride, BPSG-phosphosilicate glass, POLY-polysilicon, TEOS-silicon oxide thin films. It uses heat energy to activate the raw material gas (or liquid source gasification) to produce a chemical reaction to form a solid film on the substrate surface. Low-pressure chemical vapor deposition is carried out under low pressure. Due to the low gas pressure and the large mean free path of gas molecules, the uniformity of the grown film is good, and the substrate can be placed vertically and the loading volume is large. It is particularly suitable for industrial production of large-scale integrated circuits, discrete devices, power electronics, optoelectronic devices and optical fibers. It adopts computer industrial control software control mode, and its performance and technical indicators have reached the international advanced technical level.

2. Equipment type parameters:

3. Main features and advantages of the equipment

1★With powerful operation functions, windows interface, display screen operation, users can easily modify process control parameters and display various process states at any time; equipped with fault self-diagnosis software, which can greatly save maintenance time;

2★Adopt high-reliability industrial computer + PLC mode to fully automatically control the furnace temperature, advance and retreat boat, gas flow, valve, etc., and realize the automation of the entire process;

3★The program can realize manual/automatic operation. After power failure or mid-stop, the temperature can be manually increased according to the process when restarted, saving process time;

4★With a variety of process pipelines, users can choose conveniently;

5★The cold end uses PT100 to detect the ambient temperature for temperature compensation to avoid the influence of ambient temperature changes on the furnace temperature and avoid inter-layer interference;

6★ The push-pull boat is loaded with SIC cantilever slurry to avoid dust generated by friction with the process pipe. After the push-pull boat runs a cycle, the position is automatically calibrated to effectively prevent positioning deviation;

7★Gas flow is precisely controlled by digitalization, closed-loop control by analog signals, strong and weak electricity are separated, and various data interactions use standard buses to improve anti-interference capabilities and ensure data security; gas opening has a slow start function;

8★With multiple alarm functions and safety protection functions;

9★Automatic adjustment of constant temperature zone and cascade control can accurately control the actual process temperature of the reaction tube;

○ Company Profile

Qingdao Yuhao Microelectronics Equipment Co., Ltd. was established in 2008 as a high-tech enterprise integrating R&D, manufacturing, and sales. The company specializes in electric heating furnace equipment, heating furnace thermal fields, and graphite tool processing. Our products and services cater to various industries including electronic components, semiconductor materials, and solar photovoltaic sectors.

?

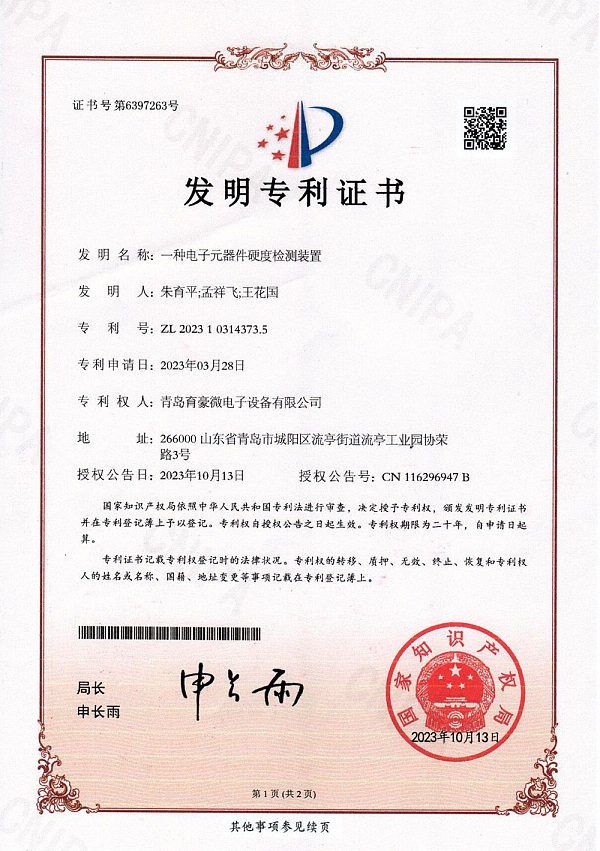

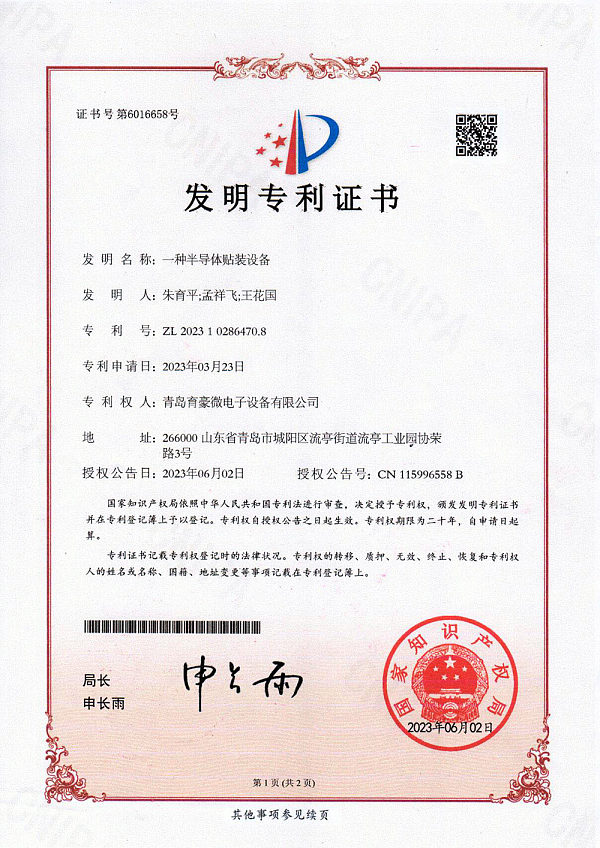

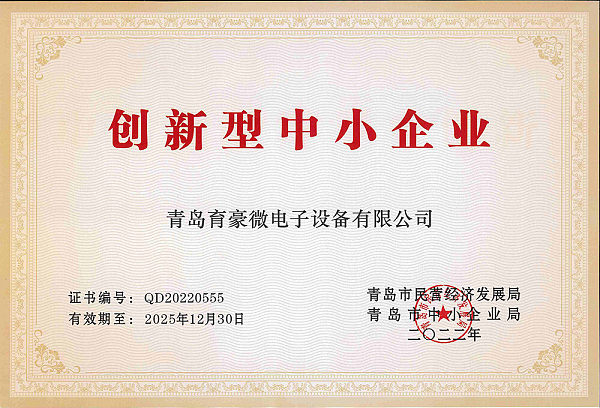

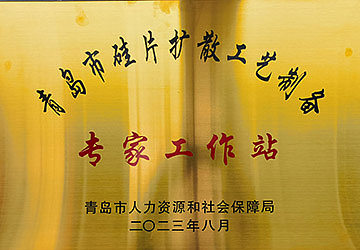

Yuhao is a national high-tech enterprise and a provincial specialized and innovative SME. We hold trademark registration rights and import/export operation licenses, having passed ISO9001 quality management system certification with over 50 patents.

○ Company Certifications

○ Online Consultation

○ Related Recommendations

Message Consultation